Plaster Silicone Vacuum Casting Prototype Process For Plastic Parts

Product Description

Plaster Silicone Vacuum Casting Prototype Process For Plastic Parts

Specifications:

| Item Name: | Plaster Silicone Vacuum Casting Prototype Process For Plastic Parts

|

| Company Name: | Shanghai Langjue Mould Co., Ltd. |

| Certification Have | ISO9001:2008 |

| Materials Available | Plastics: ABS, PC, PV, PMMA, POM, PA(NYLON), RUBBER, Silicone ) metal:Aluminum, Copper, Brass, Stainless Steel,Sheet Metal. ) |

| Available rapid prototyping processes: | 1,Prototype design 2,CNC rapid prototype 3,SLA/SLS prototypes 4,Silicone mould and vacuum casting(Rapid Tooling) |

| Leading Time: | 5-7 working days |

| Surface treatment available: | Paint, polish, silk-screen printing, anodize, transparent surface, translucent surface, brush, rubber oil, electroplat |

| Available format | Pro/E, Solidworks, Unigraphics, Auto CAD, igs, stp, stl, x-t |

| The fields we can serve: | 1. Electronic,digital camera,mp3/mp4,coffe oven,hair dryer,LED light case, television, calculators, GPS electronics, DVD/VCD player and etc 2.Medical decives,B Ultrasound scanner case, Ultrasonic diagnostic imaging care, and etc 3.Telecommunications: micro phone, speaker, monitor case, computer and etc. 4.Auto parts: dashboard, car lamp, bar, car door, motorcycle, scooter, bike and etc. 5.Household appliance: Cooker, air conditioner, TV, fan, shower, fridge, coffee machine and etc 6.Kitchenwares,crafts,perfume bottle,lighter,kitchenware,cookie molds,and etc. 7.Toys,game handle/controller,toy plane and etc. |

| Our service: | 1.Surperior in quality and morderate in price 2.Fast delivery time 3.More than10 years professional experience 4.We uphold the principle of integrity to offer the best service |

Our Advantages:

| Extremely strong and light weight | Nice looking with competitive |

| Corrosion resistance | Abrasion- resistance |

| Low coefficient thermal expansion | Impact resistance |

| durable and long-lasting | Environmentally safe |

| Non-magnetic electromagnetic | Wide temperature range use |

| Ease of fabrication & installation | Excellent fatigue resistance |

| Without residual glue after remove | Convenient to construct |

| Good resilience | Convenient to pack and transport |

| Tensile strength | UV resistance |

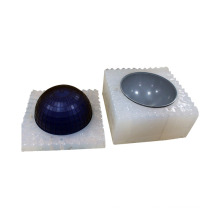

Products show

More related casting silicone mould for your reference:

Shanghai Langjue Mould Limited is established in 2008 in Shanghai China, with ISO 9001:2015Certificate.

There are 23 production lines, over 10000 square meters workshop, with about 300 employees including 42 senior technicians in the R&D Team.

Focused on designing, producing and selling industrial molds, high precision CNC parts, 3D printing,sheet metal,carbon fiber etc. With low MOQ one piece.

Five stars service is always ready for you!

--Standard exporting package: Vacuum bag/foam bag/carton, etc

--Shipping: By international express(DHL, UPS, TNT, FedEx……), by airfreight, by boat (As your choice)

Product Categories : 2. Mould > Silicone Mould/Vacuum Casting

Premium Related Products